- Home

- News

- Some principles that need to be considered in the design of sheet metal products must be clear in the design!

Some principles that need to be considered in the design of sheet metal products must be clear in the design!

The metal materials commonly used in the hardware parts we often use include stainless steel, copper, aluminum, zinc alloy, magnesium alloy, steel, iron, etc.

According to different processing methods, hardware products are often divided into cold processing and hot processing, and different types of metal forming methods are also different. Cold processing materials such as sheet metal are mainly formed by die cold stamping, bending, deep drawing and other processes. Hot working parts, such as casting parts, are mainly made by melting hardware raw materials into liquid and casting with molds.

It is generally believed that all sheet metal materials with uniform thickness are collectively referred to as sheet metal. Commonly used sheet metal materials include stainless steel, galvanized steel plate, tinplate, copper, aluminum, iron, etc.

❶ principle of uniform product thickness

Sheet metal is a material with uniform thickness, which should be paid attention to in structural design, especially where there are many bends, it is easy to cause uneven thickness.

❷ principle of easy flattening

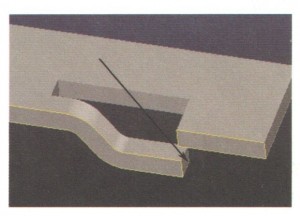

Sheet metal products are processed from sheets. Before processing, the raw materials are flat. Therefore, when designing sheet metal parts, all bends and inclined planes should be able to unfold on the same plane without interference. For example, the design of sheet metal parts shown in Figure 1-1 is unqualified because they interfere with each other after unfolding.

❸ the principle of selecting the thickness of sheet metal parts appropriately

The thickness of sheet metal parts varies from 0.03 to 4.00mm, but the greater the thickness, the more difficult it is to process, the greater the need for processing equipment, and the defect rate increases. The thickness shall be selected according to the actual function of the product. On the premise of meeting the strength and function, the thinner the better. For most products, the thickness of sheet metal parts shall be controlled below 1.00mm.

❹ conform to the principle of processing technology

Sheet metal products should conform to the processing technology and be easy to manufacture. Products that do not conform to the processing technology cannot be manufactured, that is, unqualified design.