Introduction to common processing methods and equipment of sheet metal.

Definition:

A comprehensive cold working process for metal plate, mainly divided into shearing, punching, bending, riveting, mold forming, welding, etc. Commonly used plates include hot rolled plates, pickled plates, cold rolled plates, galvanized plates, copper plates, aluminum plates, aluminum profiles, stainless steel plates, etc.

Common processing methods:

1. Sheet metal processing of plates by cnc punching machine, cnc bending machine, laser cutting machine, shearing machine and other equipment, which is mostly used for sample and small batch production.

2. The plate is processed by a fixed mold on a punch or press and other equipment. The speed is fast and the cost is low, but the cost of the mold is high, installation and replacement are time-consuming, and it is mostly used for mass production.

The processing process of sheet metal parts:

1. Cutting: mold, laser cutting, shearing or punching.

2. Forming: bending, forming mold.

3. Other processing: pressure riveting, riveting or tapping.

4. Welding: arc welding (TIG/MIG), resistance welding.

5. Surface treatment: powder coating, electrophoresis, electroplating, etc.

Common equipment and process introduction

Shearing machine:

Machine introduction:

The shearing machine uses a moving upper blade and a fixed lower blade, and uses a reasonable blade gap to apply shearing force to metal sheets of various thicknesses to make the sheets break and separate according to the required size.

Process introduction:

Used for cutting strips, it is mainly used for the preparation of die blanking processing, or the blanking of simple parts with regular shapes. Fast speed, low cost, low precision, can only process strips or blocks without holes and corners.

Laser cutting machine:

Machine introduction:

Use high-energy laser to irradiate the material to be cut. The material is vaporized to create a cavity, and the beam moves to form a slit. Cut out the structural shape of the part. Need to write laser program. It can cut various parts with complex shapes. High precision. Mostly used for sample production or multiple varieties of small batch product.

Process introduction:

The beam diameter of laser cutting is very small, usually below 0.2MM. When cutting carbon steel plates below 3 mm, the hole center distance tolerance can be controlled within 0.05MM, the contour tolerance can be controlled within 0.1MM, and the surface roughness can reach Ra 12.5. The laser will leave marks on the cutting surface. The thicker plate, the more obvious.

Influencing factors of laser cutting:

The smaller the laser cutting spot, the smaller the slit, the higher the accuracy;

The higher the positioning accuracy of the worktable, the higher the laser cutting accuracy;

The thicker the sheet, the lower the accuracy of laser cutting and the worse the surface roughness;

With the same thickness, the precision of the steel plate is higher than aluminum plate, and the cutting surface is smoother;

CNC Punching machine:

Machine introduction:

An automatic punching machine equipped with numerical control. Through CNC programming instructions, manipulate the action of the punch and fabricate parts.

Process introduction:

Through a simple mold combination, a variety of complex pass and shallow stretch parts can be completed at one time. It can process large round holes, square holes, waist holes and various shapes of curve contours. This also can be processed by special processes, such as blinds, countersinks, flanging holes, ribs, embossing, etc.

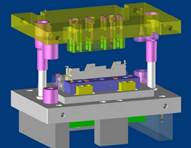

CNC stamping machine:

Machine introduction:

Stamping machine is a pressure machine. Stamping machine and mold apply external force to plates, strips, pipes and profiles to cause plastic deformation or separation, so as to obtain the required shape and size of the product forming method

Process introduction:

Through the mold, blanking, punching, forming, stretching, trimming, fine blanking, shaping, riveting and extrusion can be made. The processing accuracy depends on mold and material. Mold replacement and adjustment time is longer. The mold cost is high. Suitable for mass products.

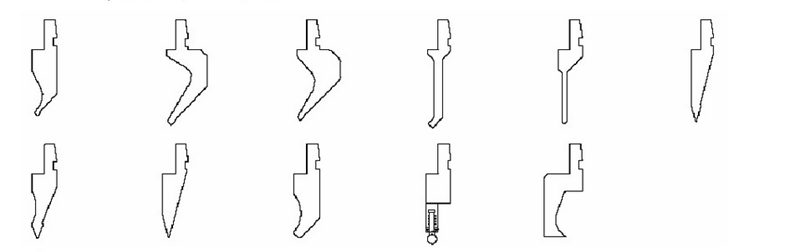

CNC bending machine:

Machine introduction:

Equipment for bending thin plates through molds. The operation is simple, and the workpiece with the side wall can be fabricated. Fast speed, high precision, and it has an automatic compensation function.

Common bending die (upper mold) shape:

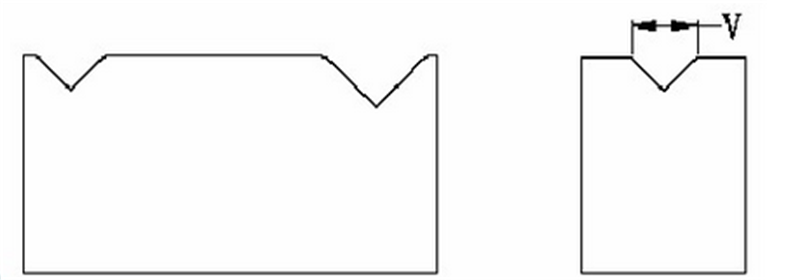

Common V groove (lower mold) shape:

Welding machine:

Machine introduction:

The welding machine instantly converts electrical energy into heat. It can instantly connect the same metal material (also can connect dissimilar metals, but the welding method is different) permanently.

Process introduction:

The common welding methods in sheet metal parts are wire welding, melting welding and laser welding. Laser welding is suitable for thin plates and products with high surface requirements. AC welder welds aluminum parts. DC welding machine welding iron, stainless steel, etc

If you have sheet metal or other metal product fabrication demands, please contact with us freely. We will quote you. Maybe you meet some problem or questions during fabrication or design, also can send into sales1@shhofen.com for help. We are glad to help you.